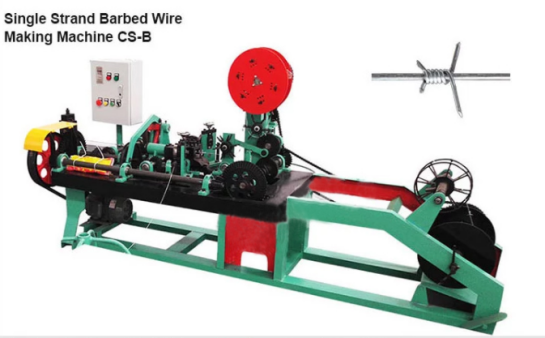

Barbed wire is a versatile fencing solution, and its performance heavily depends on twisting techniques. Understanding common twisting methods and their differences can help you choose the right barbed wire for your needs—all powered by barbed wire making machines.

Produced by standard barbed wire making machine, this method twists two wires together with barbs spaced evenly. It's cost-effective for basic fencing in farms or rural areas.

Using specialized barbed wire making machines, two pairs of wires are interwoven, creating a stronger structure. Ideal for high-security zones like prisons, it resists cutting and tampering.

Advanced barbed wire making machines twist wires in opposite directions, forming tight barbs that deter climbing. Perfect for border security or critical infrastructure protection.

The quality of barbed wire hinges on the precision of barbed wire making machines. High-end machines ensure uniform twists, durable barbs, and compliance with international standards (e.g., ASTM). For projects demanding longevity, opt for hot-dipped galvanized wires crafted by reliable machinery.

Whether for agriculture or high-threat sites, selecting the right twisting style and machine-driven manufacturing guarantees optimal security and value. Invest in quality—let advanced barbed wire making machines elevate your fencing solutions! Stay with CANDID!

How to Properly Lay Out a Gabion Production Floor to Minimize Material Handling

How to Calibrate Gabion Machine Wire Tension: Switching from Galvanized to PVC-Coated Wire

The Honest Truth: How Many Operators Do You Actually Need for a “Fully Automated” Gabion Production Line?