We specialize in manufacturing plastic extruders and have extensive experience in manufacturing rubber band extruders. Our rubber band making machines are stable and reliable, with high output, easy operation, and affordable prices. Whether you need a rubber band maker machine or a rubber band manufacturer machine, we have the right solution for you.

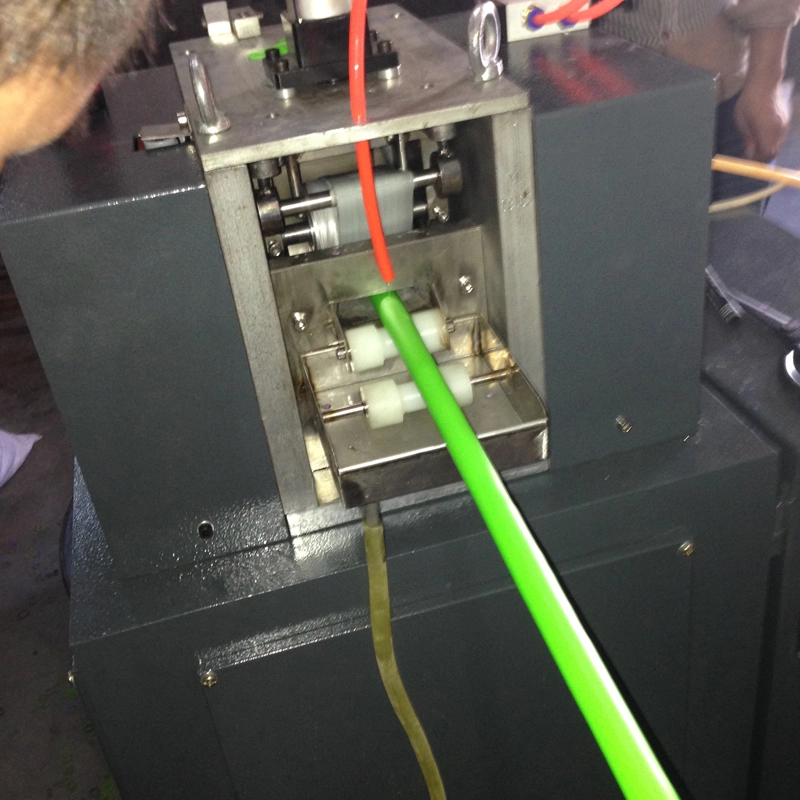

Our TPU, TPR, and SBS rubber band extrusion production lines can choose single color, dual color, tri color, or multi-color extrusion hosts according to customer production needs. Rubber bands produced by our rubber band production machines are widely used in toys, decorations, gift packaging, vegetable packaging, and other fields.

The rubber band extruder is suitable for materials such as TPU, TPR, SBS, TPE, etc.

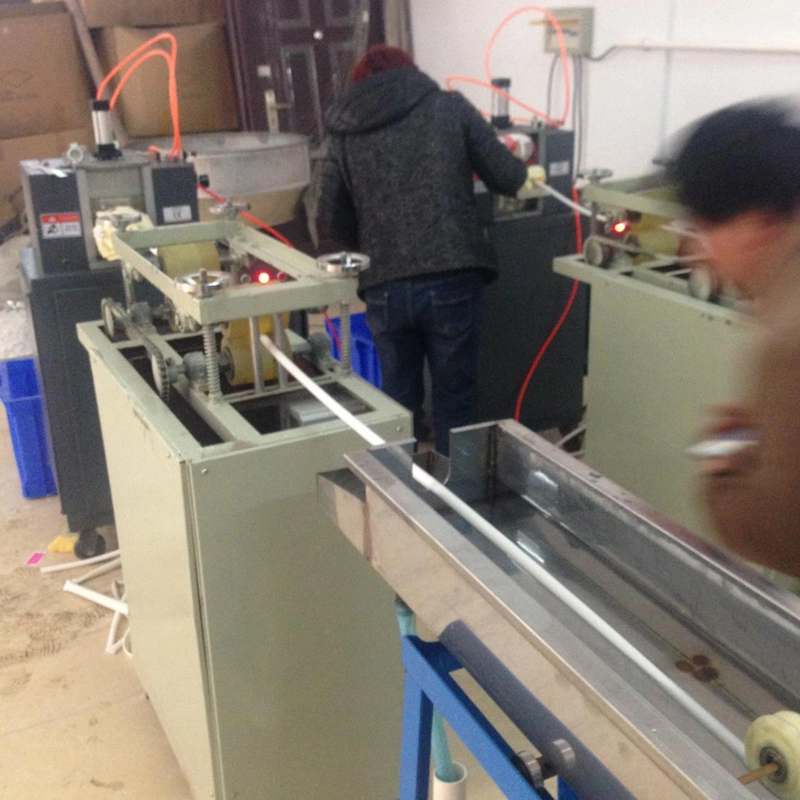

Composition of rubber band extrusion production line:

Extrusion host - Precision mold - Spray cooling water tank - Small belt conveyor traction - Rotary cutterhead cutting machine

Single screw extruder

Motor(kw) | 15 |

Frequency converter(kw) | 15 |

Nitration hardness | screw≧740HV; barrels≧940HV. |

Nitration depth(mm) | 0.3-0.7,screw: 0.4-0.6mm, barrel: 0.6-0.7mm |

Diameter of screw (mm) | 55 |

Screw Length/Diameter | 28:1 |

Die head material | 38CrMoAlA |

Production capacity: | 35-40kg/Hour |

Water tank

Length(mm) | 5000 |

Material | Stainless steel |

Pump power(kw) | 0.37 |

Dimension(mm) | 3000*420*600 |

Automatic cutting machine

Feeding motor(kw): | 0.75 |

Cutting motor(kw): | 3.7 |

Cutting style: | rotary knife |

Cutting speed(pcs/min): | 2000-2500 |

The rubber band maker machine offers a remarkable improvement in production efficiency. With full automation from raw material feed to finished loops, this machine dramatically reduces manual labour while increasing output consistency. As a core part of your manufacturing line, the rubber band making machine ensures each band meets the same diameter, thickness and roundness—something difficult to guarantee in manual processes.

Flexibility is another major strength of a well‑designed rubber band production machine. Whether you’re producing small elastic loops for office use or heavy‑duty bands for industrial packaging, the rubber band manufacturer machine allows you to adjust band size, wall thickness and material type with minimal downtime. This adaptability helps you respond quickly to changing customer demands and different market segments without investing in multiple machines.

Durability and maintenance‑ease are built into the construction of the rubber band making machine. Equipped with robust gear trains, precision extruders (in case of continuous extrusion systems), and user‑friendly controls, the machine offers long service life with fewer breakdowns. This means lower lifetime cost‑of‑ownership and less unexpected interruption to your production schedule.

Cost effectiveness also stands out. By integrating a complete rubber band maker machine into your manufacturing line you reduce waste, improve material usage, and optimise labour. Over time, the increased throughput and lower operating costs combine to give a strong return on investment—especially as demand for rubber bands continues to rise across packaging, stationery, agricultural and industrial markets.

In summary, choosing the right rubber band production machine equips your business to scale up intelligently, maintain high quality standards, and serve multiple product niches with one versatile device. Whether you are just starting or expanding your line, a modern rubber band making machine is a key investment for consistent performance, flexibility and profitability.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China

How to Properly Lay Out a Gabion Production Floor to Minimize Material Handling

How to Calibrate Gabion Machine Wire Tension: Switching from Galvanized to PVC-Coated Wire

The Honest Truth: How Many Operators Do You Actually Need for a “Fully Automated” Gabion Production Line?