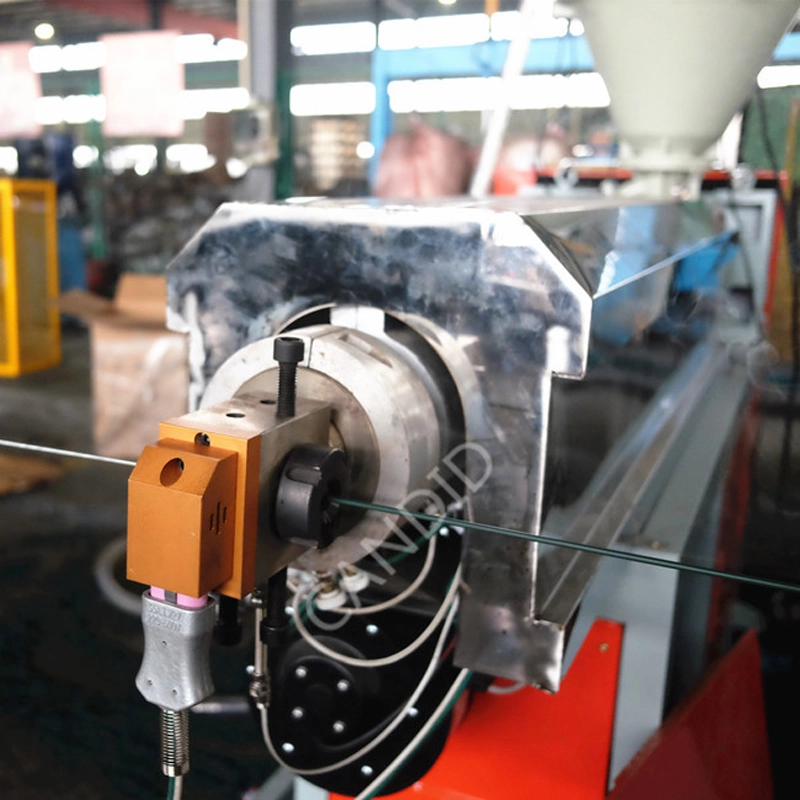

The Wire PVC Coating Machine is an advanced industrial system designed to apply a protective layer of PVC (Polyvinyl Chloride) onto metal wires.This coating provides enhanced durability, corrosion resistance, and aesthetic appeal, making the wire suitable for a wide range of applications, including fencing, electrical wiring, and construction materials.

Item | Wire PVC coating line |

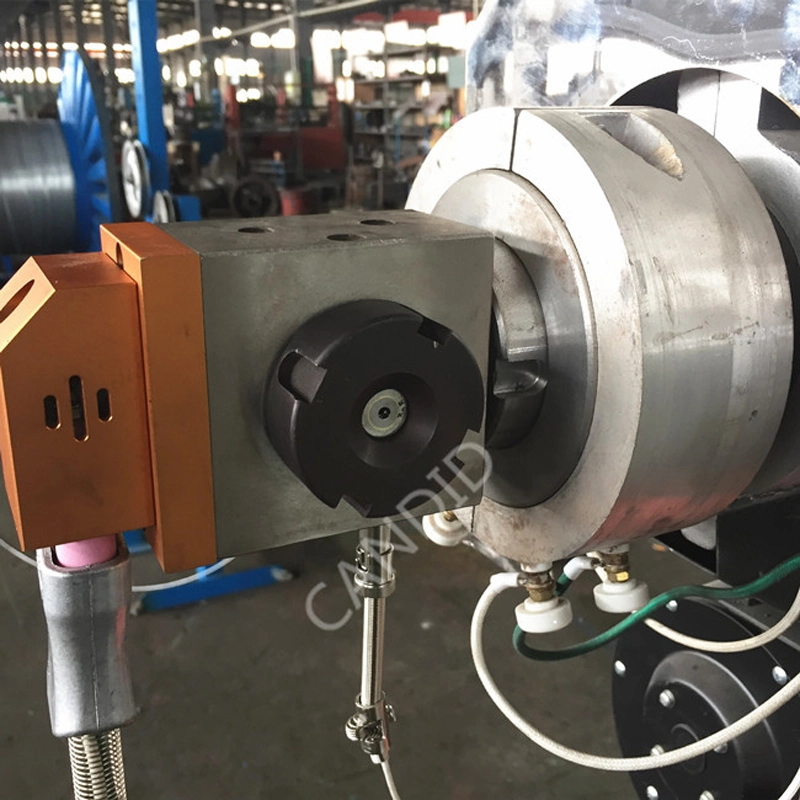

Screw diameter | 65mm |

Screw working length | 1625mm |

Screw slenderness ratio | 25:1 |

Screw revolution | 4-40r/min |

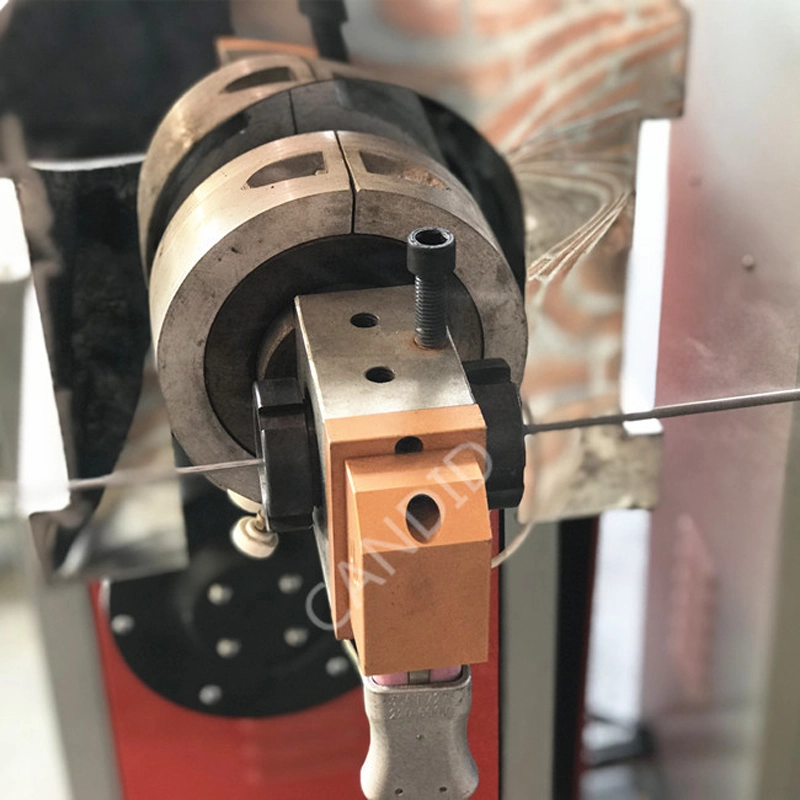

Coating thickness | 0.3-0.5mm |

Power | 15KW |

Barrel heating and cooling | heating ring and fan |

Heating zone | 5 |

Heating Power | 7.5KW |

Center height | 1000mm |

Space requirement | 20-25m(L)*4m(W) |

The pvc coating line is a game‑changer when it comes to applying uniform, high‑quality PVC coatings across a variety of substrates. With automation built into the core of the process, this coating machine allows manufacturers to streamline operations—from raw material feed, through extrusion and cooling, to final winding. The result? Higher throughput, fewer manual steps and significantly improved efficiency.

One of the standout advantages of using this pvc coating line is the precise control over coating thickness, uniformity, and adhesion it offers. Advanced controls within the machine monitor and adjust parameters like extrusion temperature, pulling speed and cooling processes, ensuring that each coated product meets strict quality standards. This level of consistency helps reduce waste, minimize defects and improve product reliability.

Durability and performance are further improved thanks to the enhanced protective properties of the PVC coating itself. Substrates treated on the pvc coating line benefit from increased resistance to corrosion, ultraviolet (UV) exposure, abrasion and even chemical attack. This means that the final product lasts longer in real‑world applications—reducing costs over time and elevating your reputation for quality.

Another key benefit is flexibility. The pvc coating line can handle a wide range of base materials—from wires and metal rods to mesh and structural components—allowing businesses to pivot across applications without needing multiple distinct machines. This adaptability keeps production lines future‐proof, and supports shifts in customer demand or product specs with minimal downtime.

Finally, investment in a full pvc coating line pays off in terms of economics and competitiveness. Because the machine automates key stages, labor costs drop, operational consistency increases, and you’re poised to meet larger production volumes at lower unit cost. Installing a high‑quality coating line positions your company to scale, serve new markets and deliver superior value to customers.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China