Steel Wire: Most commonly used material, providing strength and durability, essential for various nail types and sizes in production.

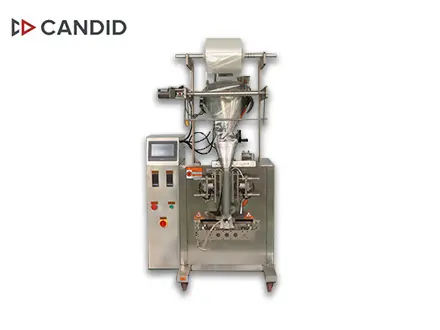

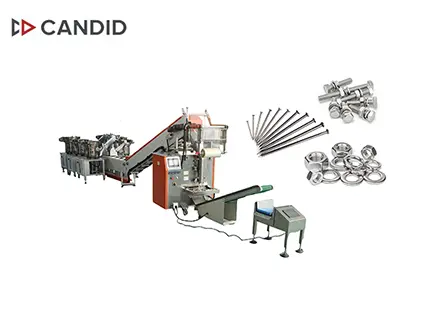

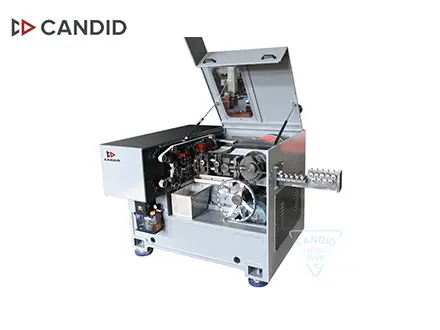

Nail making machines are essential equipment in the manufacturing of nails, widely used in construction and various industries. These machines automate the nail production process, increasing efficiency and reducing labor costs. Typically, they transform wire into nails through a series of operations, including cutting and forming. Then the nails need to be treated by nail polishing machine to ensure the good appearance. Modern nail making machines are designed for high-speed production and can handle various nail types and sizes. With advancements in technology, these machines now offer enhanced precision and reliability, ensuring consistent quality. As demand for fasteners continues to rise, nail making machines play a crucial role in meeting industry needs, so it develops different form like coil nail, roofing nail, double cap model etc. Whatever you need for nails, you can always go with CANDID

Steel Wire: Most commonly used material, providing strength and durability, essential for various nail types and sizes in production.

Aluminum Wire: Lightweight and corrosion-resistant, aluminum is ideal for specialized nails used in specific applications, such as roofing or decorative purposes or rivet

Stainless Steel: Offers superior resistance to rust and corrosion, making it suitable for nails used in outdoor or marine environments, especially for making concrete nail.

Copper Wire: Less common but used for certain types of nails, particularly in electrical applications or when aesthetics are important.

Coated Wire: Wire coated with materials like zinc or polymer enhances corrosion resistance and improves the finish of the final product while makes the surface brighter.

Specialty Alloys: Some machines can work with alloyed metals, providing unique properties like increased strength or flexibility for specific nail applications.

The nail making machine offers exceptional productivity and automation, making it ideal for manufacturers ready to scale their operations. A modern wire nail making machine transforms raw steel wire into finished nails—straight from feeding, cutting, head forming, to collection—without heavy manual intervention. This end‑to‑end automation means you’re able to produce nails at speeds and volumes far beyond traditional manual methods, lowering labour requirements and giving your business a stronger competitive edge.

Another major advantage of this steel nail manufacturing machine is its ability to deliver consistent quality while handling wide ranges of nail sizes and specifications. Whether you’re producing nails for construction, packaging, furniture, or other applications, the machine’s precise control of wire feed, cutting length, head shape, and tip sharpness ensures that every batch meets industry standards. This consistency reduces waste, improves customer satisfaction, and strengthens your reputation as a manufacturer.

Durability and operational efficiency are also built into the design of this nail making machine for sale. With features such as automated lubrication, robust drive systems, enclosed mechanisms to reduce dust and wear, and frequency‑controlled motors, this machine runs stably at high speed with low downtime. The reduced noise, lower maintenance frequency and fewer stoppages translate into real savings in overheads and maintenance cost.

Flexibility is another highlight. If you’re looking to invest via a nail making machine manufacturer that offers versatility, you’ll appreciate that this kind of machine can switch between different nail diameters and lengths with minimal setup changes. That means you can serve multiple market segments with one piece of equipment—whether you’re producing common nails, finishing nails, or heavy‑duty nails—giving you better utilization of your investment.

Finally, the cost‑effectiveness of a fully automatic wire nail manufacturing machine is hard to ignore. Because the process is automated, labor costs drop significantly; because output is high and waste is low, the cost per nail decreases. In many cases, manufacturers find that the machine pays for itself quickly through increased production capacity, reduced labour, and higher quality and value of finished nails.

To improve the quality of nails produced, start by selecting high-quality raw materials, such as durable steel or stainless steel. Ensure precise calibration of the nail making machine to maintain consistent dimensions, for example, lower the speed if the current speed is fast enough, or check the cutter and moulds period. Regularly maintain and lubricate machinery to prevent wearing parts. Implement quality control checks throughout the production process to catch defects early. Optimize the manufacturing speed to avoid overheating or deformities. Additionally, consider investing in advanced technology to enhance accuracy and reliability. We will train operators on best practices, which can also improve overall production quality.

Regular maintenance of a nail making machine is essential for optimal performance and longevity. Key tasks include daily inspections for the wearing parts, ensuring all moving parts are properly lubricated to prevent friction. Monthly checks should focus on electrical connections and control systems to ensure safe operation. It's important to clean the machine regularly to remove debris and metal shavings, which can impede function. Additionally, replacing worn-out components, such as dies and cutters, should be scheduled to maintain production quality. A thorough annual maintenance review by a qualified technician can help identify potential issues before they escalate.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China

How to Properly Lay Out a Gabion Production Floor to Minimize Material Handling

How to Calibrate Gabion Machine Wire Tension: Switching from Galvanized to PVC-Coated Wire

The Honest Truth: How Many Operators Do You Actually Need for a “Fully Automated” Gabion Production Line?