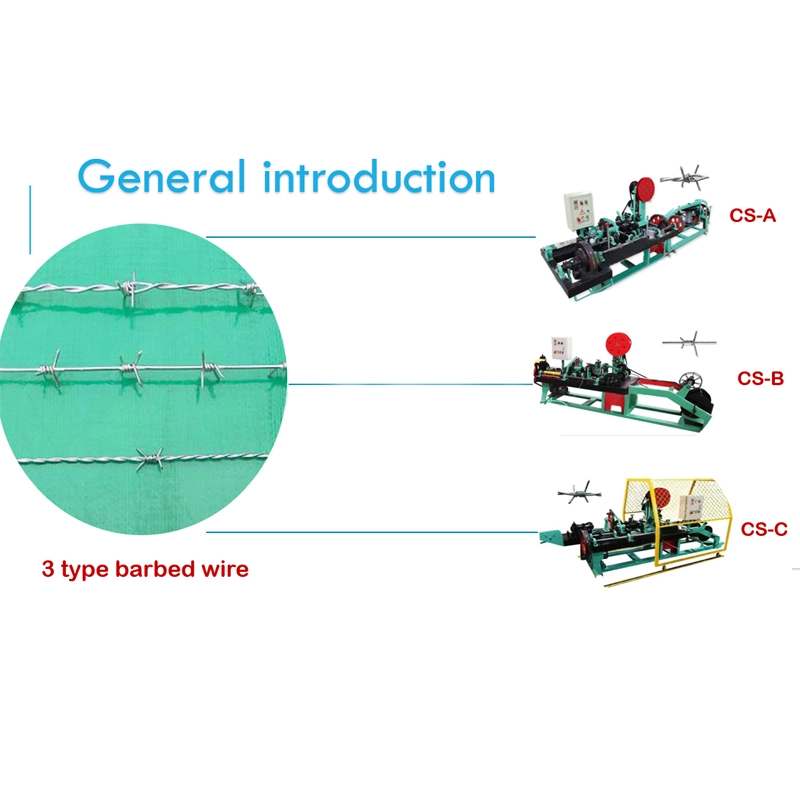

This machine can produce positive and negative twisted barbed wire which is widely used in national defense, military, railway, highway, animal husbandry and other industries.

The materials used for positive and negative twisted barbed wire are usually hot dipped galvanized wire, electric galvanized wire etc.

Positive and negative twisted barbed wire use positive and negative way for winding flowers, the barbed wire products produced has no rebound and winding phenomenon, so it is more beautiful compared with the general barbed wire.

Get a Quote | Unit | CS-A Type | CS-B Type | CS-C Type | |

| Motor power | kw | 2.2/3 | 2.2/3 | 2.2/3 |

| Voltage | V | 380v 50Hz or customized | ||

| Main drive shaft speed | r/min | 402 | 355 | 355 |

| Strand wire diameter | mm | 1.6-3.0 | 2.0-3.0 | 1.6-2.8 |

| Barb wire diameter | mm | 1.6-2.8 | 1.6-2.8 | 1.6-2.8 |

| Barb pitch | inch | 3/4/5/6 | 3/4/5/6 | 3/4/5/6 |

| Twisted number | / | 3-5 | 3 | 7 |

| Raw material | / | Galvanized steel wire, PVC coated wire, black wire etc. | ||

| Production | / | 20m/min | 17m/min | 17 m/min |

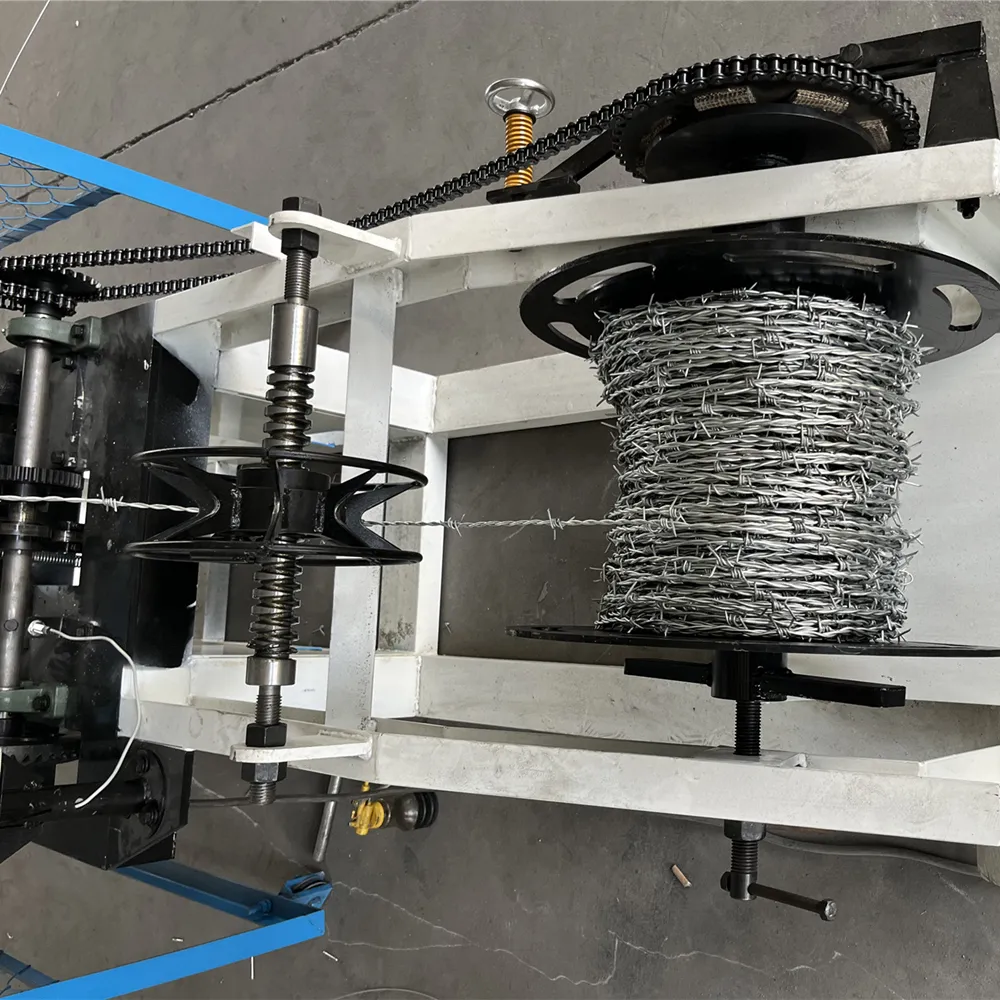

The barbed wire manufacturing machine delivers outstanding productivity and precision, making it a powerful asset for any fencing‑wire production facility. Designed for continuous operation, the machine automates the key steps of wire feeding, barb formation, twisting and rolling, which significantly reduces labour requirements and allows manufacturers to achieve high‑volume output with consistent quality.

One of the major advantages of the barbed wire fencing making machine is its flexibility in handling various specifications. Whether you’re producing single‑strand, double‑strand or reverse‑twist barbed wire variants, this machine is capable of adjusting barb spacing, line‑wire diameters and barb diameters to suit agricultural fencing, perimeter security or industrial barrier applications. This flexibility ensures your production line can respond swiftly to market demands without expensive change‑overs.

Durability and stability under heavy production loads are built‑in features of this barbed wire making machine. It’s typically equipped with high‑quality motors, low‑noise drives and safety covers that protect both the equipment and operators. Because of its robust structure and reliable components, downtime is minimized — translating into better overall equipment effectiveness (OEE) and lower lifetime maintenance costs.

Another key benefit lies in the improved cost‑effectiveness achievable through this barbed wire manufacturing machine. With automation in place, material waste is reduced — precise feeding and cutting mean fewer rejects, and consistent twisting means less re‑work. Furthermore, as operator intervention declines, labour costs come down. All this adds up to a lower cost per metre of finished barbed wire, helping producers remain competitive in demanding markets.

Finally, for companies seeking scale, the fully automatic barbed wire machine makes growth realistic. By enabling continuous, high‑speed production of barbed wire rolls, you are able to meet large orders, enhance lead‑time responsiveness, and deliver uniform product quality across batches. Choosing the right barbed wire making machine manufacturer ensures the machine integrates smoothly into your existing infrastructure and supports future expansion.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China

How to Properly Lay Out a Gabion Production Floor to Minimize Material Handling

How to Calibrate Gabion Machine Wire Tension: Switching from Galvanized to PVC-Coated Wire

The Honest Truth: How Many Operators Do You Actually Need for a “Fully Automated” Gabion Production Line?