For decades, entering the staple manufacturing industry meant a significant upfront climb. Investing in bulky wire drawing, flattening, and gluing lines required vast space, substantial capital, and technical expertise before the first staple was even made. Those days are over.

Introducing the Next Evolution: From Single Wire to Multi wires

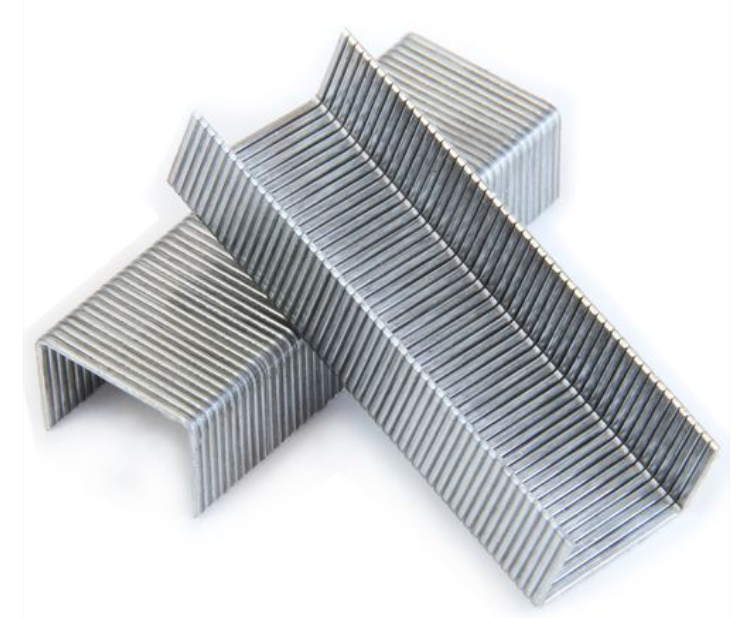

We revolutionized the core of high-speed staple production. Our flagship equipment doesn't just improve the old process; it redefines it. By shifting the feedstock from a single spool of wire to a ready-to-use flattened wire belt —a precision-engineered ribbon of 100-200 pre-flattened, adhesive-bonded wires—we have unlocked unprecedented speed and simplicity.

The Power of Parallel Processing.

Think of the difference between writing a sentence one letter at a time versus stamping the entire word simultaneously. Our technology applies this principle. For high speed staple making machine processes a complete flattened wire belt in a single, continuous motion. This parallel processing is the engine behind our staggering output of 12,000 to 18,000 staples per minute.

Your Fastest Path to Production: The All-in-One Solution.

We understand that new entrants need a lean, efficient launch. That's why we offer more than just the machines; we provide the complete key to immediate operation.

1. The Heart: High-Speed Staple Machine

Experience relentless, precision engineering designed for maximum uptime and jaw-dropping output, setting your productivity benchmark from day one.

2. The Lifeline: Ready-to-Feed flattened wire belt

Eliminate the entire front-end complexity. We supply the core raw material—the staple flattened wire belt—prepared to our exacting specifications. This removes your need for:

Separate wire drawing and flattening machinery.

Sophisticated adhesive application and bonding systems.

The significant factory floor space they consume.

The specialized labor and technical overhead to manage them.

The Strategic Advantage for Your Business:

Minimal Initial Investment: Redirect capital from auxiliary equipment to core business growth. Your startup costs are dramatically lower.

Lightning-Fast Setup: Your production line is operational in record time. Go from installation to revenue-generating output faster than ever imagined.

Reduced Operational Footprint: A compact, streamlined setup means a smaller factory requirement and lower overhead.

Inherent Consistency & Quality: Our precisely manufactured staple flattened wire belt ensures uniform input material, leading to superior and consistent staple quality with less waste.

Engineered for Your Success.

We CANDID Machinery are not just equipment manufacturers; we are your partners in building a competitive and agile production facility. Our integrated solution of cutting-edge machinery and ready-to-use Line Board is designed to lower barriers, accelerate your time-to-market, and give you a decisive edge.