Are you planning to expand your stationery production line with colorful, vinyl-coated paper clips?

It’s a smart move. The demand for color-coded office supplies is growing.

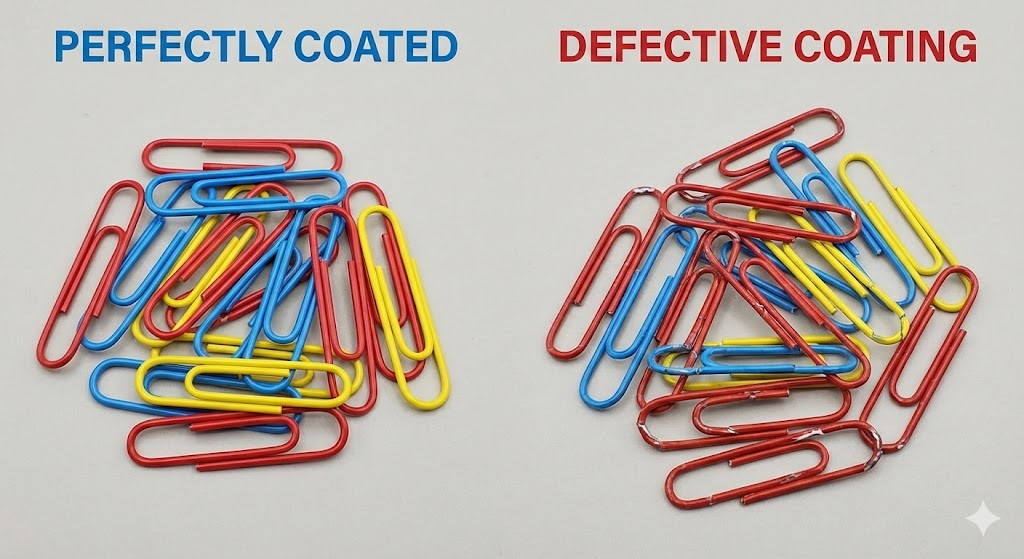

However, manufacturing vinyl-coated clips comes with a specific set of challenges. Unlike standard galvanized wire, vinyl-coated wire is delicate. If your machine isn't set up correctly, you’ll end up with scratched surfaces, peeling coatings, and high rejection rates.

In this guide, we will share the technical secrets to producing flawless vinyl-coated paper clips using China-Equipments' advanced forming technology.

Before we touch the machine, we must understand the wire. Vinyl-coated wire typically consists of a steel core (often galvanized) wrapped in a PVC or PET plastic layer.

The Challenge: The plastic layer adds thickness but lacks the hardness of steel.

The Risk: Standard steel feed rollers can "bite" into the soft plastic, causing invisible micro-cracks that expand when the wire is bent.

Pro Tip: For high-speed production, ensuring the concentricity of the wire coating is crucial. If the coating is thicker on one side, the clip will twist during forming.

This is where many generic machines fail.

Standard paper clip machines use aggressive knurled rollers to grip the wire. This works for steel, but it destroys vinyl.

At China-Equipments, our Vinyl Coated Paper Clip Forming Machine utilizes a specialized feeding system:

Polyurethane or Polished Carbide Rollers: We replace rough steel rollers with smoother, material-friendly alternatives that provide grip without surface damage.

Adjustable Tension Control: Our machines allow for micro-adjustments in feeding pressure. This ensures the wire is pushed forward with the exact force needed—no more, no less.

To achieve the perfect "gem clip" shape without cracking the coating at the sharp bends, follow these setting guidelines:

A. Slow Down (Just a Little)

While our machines are capable of high speeds (up to 180+ pcs/min), running vinyl wire at maximum capacity can generate excess heat from friction, softening the plastic. We recommend running at 85-90% max speed for optimal finish quality.

B. Molds & Tooling Clearance

The gap in your forming tooling is critical.

Too tight: The coating will be stripped off.

Too loose: The clip shape will be inconsistent.

Our machines come with CNC-machined tooling sets specifically calculated for standard vinyl wire gauges (e.g., 1.0mm core + 0.2mm coating).、

| Defect Issue | Possible Cause | The Fix |

| Coating Peeling at Bends | Bending speed too high or tooling radius too sharp. | Reduce speed; check if the mold radius matches the wire gauge. |

| Wire Slipping | Feeding rollers are too loose or oily. | Clean the rollers; increase tension slightly. |

| Twisted Clips | Wire quality issue (eccentric coating). | Test a different batch of wire. |

| Surface Scratches | Burrs on the cutting knife or guide tube. | Polish the guide tube exit; sharpen or replace the cutter. |

You don't need just a machine; you need a low-defect production process.

Our Automatic Paper Clip Making Machine series is trusted by manufacturers in over 30 countries because we understand the nuance of materials.

Precision CNC Controls: ensuring every bend is identical.

Dedicated Tooling: Specific kits for vinyl vs. galvanized wire.

Long-Term Durability: Machines built to run 24/7 with minimal maintenance.

Producing vinyl-coated paper clips can yield higher profit margins, but only if your scrap rate is low. Don't let poor machinery eat into your profits.

Ready to upgrade your production line?

[Contact Us Today]: Get a free consultation on which machine model fits your wire specifications.

[Watch Video]: See our machine producing vinyl clips at 160 pcs/min without a single scratch.

How to Produce High-Quality Vinyl Coated Paper Clips: Machine Settings & Wire Guide (2026 Edition)

High-Speed Automatic Paper Clip Making Machine: 2026 Buying Guide & Profit Analysis

How to Start a Profitable Staple Manufacturing Business in 2026: Costs, Machinery, and ROI