The global stationery market is steady, but the real opportunity lies in consumables. Unlike office chairs or desks, staple pins are used and replenished daily in offices, schools, and packaging facilities worldwide.

However, the difference between a struggling workshop and a highly profitable factory in 2026 often comes down to one factor: Automation Efficiency.

In this guide, we break down exactly how to launch a staple manufacturing business, calculate your ROI, and choose the right equipment to outperform the competition.

Before buying a single wire, you must understand your product. The demand is split into two categories:

Office Series: Standard 24/6 and 26/6 staples (High volume, thin margin).

Industrial Series: Heavy-duty staples for furniture and packaging (Lower volume, higher margin).

The Strategy: To succeed, your production line needs the versatility to switch between these specifications. This is where advanced machinery plays a pivotal role.

Your machine is your money printer. In the past, factories required separate machines for wire flattening, gluing, and forming. Today, Integrated Automatic Staple Making Machines handle the entire process.

Why Choose Our Automatic System?

High Speed: Capable of producing significantly more pins per minute than semi-auto models.

Precision Forming: Avoids the common issue of "jamming pins" which ruins brand reputation.

Labor Saving: One technician can supervise multiple running machines.

Featured Equipment: Check out our High-Speed Staple Making Machine. It is designed specifically for entrepreneurs looking for stability and high output.

To calculate your profit, you need to know your inputs. The manufacturing process requires two main materials:

Galvanized Iron Wire: The quality of the wire determines the hardness of the staple.

Flattening Glue: Special adhesive is needed to bond the wires into a "band" before cutting.

Pro Tip: Our machine's precise gluing system ensures you use just enough adhesive, reducing material waste by up to 15% compared to older models.

This section establishes your Authority (E-E-A-T) by helping the user do the math.

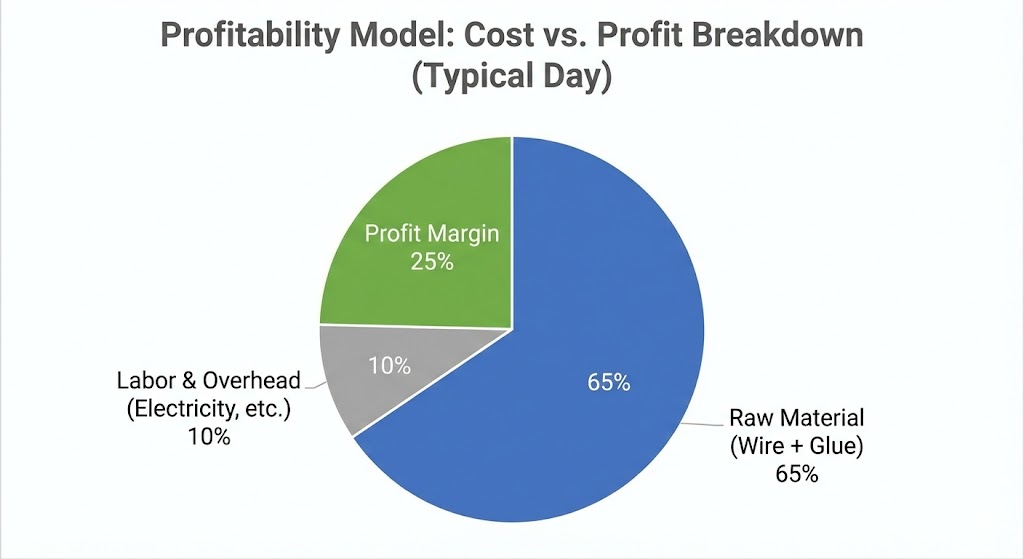

Let's look at a hypothetical profitability model for a standard production day:

| Cost Factor | Description | Impact on Profit |

| Raw Material | Wire + Glue cost per ton | High (approx. 60-70% of cost) |

| Electricity | Running the 3-Phase motor | Low (Our machines are energy efficient) |

| Labor | Operator wages | Very Low (with Automation) |

| Output Value | Market price of finished boxes | High |

The ROI Verdict:

With a fully automatic line, most of our clients report breaking even on their machinery investment within 12 to 18 months, depending on local raw material prices and sales volume.

You don't need a massive factory to start.

Space: A single production line is compact. A 50-100 sqm workshop is often sufficient to start.

Power: Ensure you have access to industrial 3-phase electricity.

Logistics: Plan for storage space for raw wire coils and finished boxes.

Optimized to capture Featured Snippets in Google and AI answers.

Q: Is the staple making business profitable in 2026?

A: Yes. Because staples are a consumable product with consistent global demand, the business is stable. Profitability depends heavily on using high-speed, automated machinery to minimize labor costs.

Q: Do I need experience to operate the machine?

A: No. Modern machines like ours come with user-friendly control panels. We also provide full training and manuals to get you started.

Q: Where can I buy a reliable staple making machine?

A: You should source directly from experienced manufacturers to ensure after-sales support. Visit our Product Page to see the machine specs.

The staple manufacturing industry rewards efficiency. Don't let outdated manual machines eat into your profits.

Ready to calculate your specific ROI?

Contact our engineering team today for a free consultation and let us help you build a production line that fits your budget.

View Machine Specifications & Get a Quote

How to Start a Profitable Staple Manufacturing Business in 2026: Costs, Machinery, and ROI

The Definitive Guide to Stapler Making Machines (2026): Efficiency, ROI, and Smart Manufacturing

Heavy-Duty vs. Standard Gabion Mesh Machines: The Engineer’s Guide to Choosing the Right Equipment