In the rapidly evolving stationery industry, one trend is undeniable: The era of PVC is ending, and the age of TPR (Thermoplastic Rubber) has arrived.

For decades, PVC (Polyvinyl Chloride) dominated the eraser market due to its low cost. However, with increasing environmental regulations in Europe (REACH) and the USA (CPSIA), along with a growing consumer demand for non-toxic school supplies, stationery manufacturers face a critical choice: Adapt or get left behind.

If you are a stationery factory owner still relying on traditional PVC extrusion lines, here is why upgrading to a Specialized TPR Eraser Extruder is the smartest investment you can make this year.

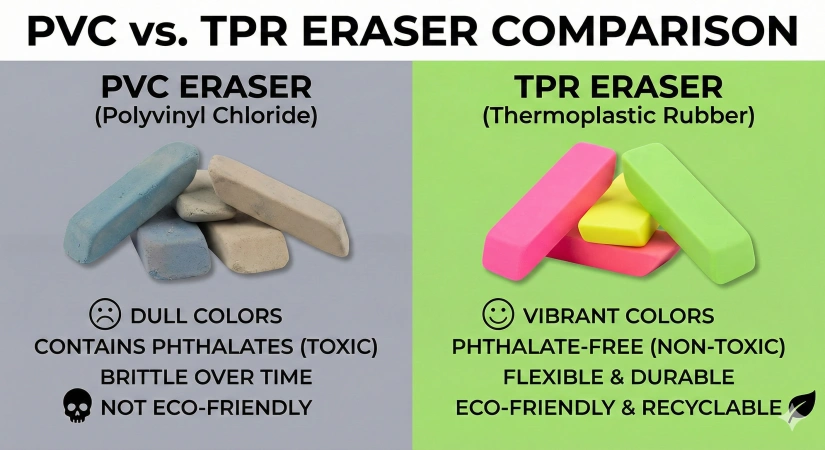

The biggest driver for the shift to TPR is safety. PVC erasers often contain phthalates (plasticizers) to make them soft. These chemicals are now strictly regulated or banned in children's products in many major markets.

Global Compliance: TPR is naturally phthalate-free and non-toxic. It easily passes EN71-3, REACH, and ASTM standards.

Market Demand: Premium stationery brands and big-box retailers (like Walmart, Target, Tesco) are actively seeking "PVC-Free" labels.

The Risk: Sticking to PVC limits your export potential to low-end markets with shrinking margins.

Why do buyers prefer TPR? It’s not just about safety; the product quality is superior.

| Feature | Traditional PVC Eraser | TPR (Thermoplastic Rubber) Eraser |

| Eco-Friendliness | Low (Contains Chlorine/Phthalates) | High (100% Recyclable, Non-toxic) |

| Erasing Power | Good, but produces more dust | Excellent, less dust (Dust-Free) |

| Texture | Can harden over time | Soft touch, stable over time |

| Coloring | Limited brightness | Vivid, accepts neon/pastel colors well |

| Profit Margin | Low (Price war) | High (Premium product) |

This is the most common question we get at China Equipments: "Can I just put TPR granules into my old PVC extruder?"

The short answer is: No, not efficiently.

While TPR and PVC are both extruded, their processing behaviors are different. Using a standard PVC screw for TPR material often leads to:

Poor Plasticization: The material isn't melted evenly, causing white spots.

Unstable Output: Inconsistent diameter leads to waste during cutting.

Temperature Issues: TPR is more sensitive to shear heat. Old PVC screws generate too much friction heat, which can degrade the TPR material and ruin the color.

To produce high-quality TPR erasers that compete in the global market, you need a machine designed specifically for the rheology of Thermoplastic Rubber.

At China Equipments, we have engineered a dedicated TPR Eraser Extruder designed to solve these production headaches. Unlike generic plastic extruders, our machine offers:

We use a custom L/D ratio and screw geometry specifically for TPR. This ensures low-temperature plasticization, meaning the material melts fully without burning. The result? A smooth, glossy surface ("Sharkskin-free") and vibrant colors.

Our machines utilize advanced PID temperature control systems combined with air cooling for the barrel. This maintains the temperature within ±1°C, essential for stable continuous production.

Want to make 2-color strip erasers or sandwich erasers? Our co-extrusion technology allows you to combine multiple extruders with one die head, creating perfect bonding between different colored layers.

We don't just sell machines; we sell solutions. For new entrants to the TPR market, we provide mature TPR eraser formulas, helping you skip the R&D phase and start production immediately.

The transition from PVC to TPR is inevitable. By upgrading your equipment now, you position your factory as a premium supplier capable of meeting international safety standards.

Don't let outdated machinery hold your business back.

Ready to upgrade?

Check out our Automatic Eraser Making Machine page to see the technical specifications, or contact us today for a free consultation and TPR formula guidance.