Our company has completed the high-precision manufacturing of a PVC extrusion mold, specifically designed for use in a PVC wire coating production line. The precision involved in creating this mold offers several significant advantages that directly impact the quality and efficiency of the production process.

High-precision manufacturing ensures that the mold is made with exacting tolerances. This means that every dimension and contour is precisely as intended, leading to consistent and uniform output. In the context of PVC wire coating, this translates to a smooth, even coating that adheres perfectly to the wire. The result is a high-quality, durable product with a professional finish. Precision also extends the life of the mold. By minimizing imperfections and ensuring proper alignment, the mold can withstand the rigors of continuous use without degrading. This reduces the need for frequent replacements and lowers overall maintenance costs, contributing to a more cost-effective production process.

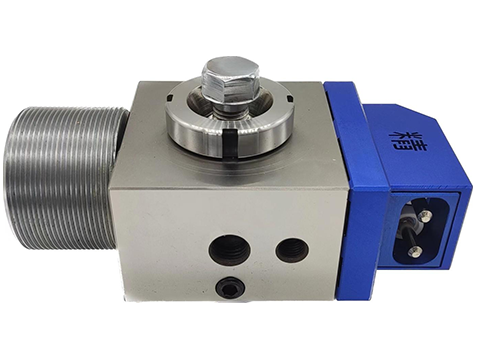

The principle behind a PVC extrusion mold is relatively straightforward but highly effective. PVC, a versatile and widely-used material, is fed into an extruder where it is heated and softened. The softened PVC is then forced through the mold, which shapes it into the desired profile. In the case of wire coating, the mold is designed to apply a uniform layer of PVC around a metal wire. The wire passes through the center of the mold, and the PVC is extruded around it, creating a seamless coating. Once the PVC exits the mold, it is cooled and solidifies, forming a durable, protective layer around the wire.

This specific mold is designed for use in a PVC wire coating production line, where it plays a crucial role in enhancing the quality and durability of the final product. The high-precision manufacturing ensures that the PVC coating is applied evenly and consistently, providing a smooth, defect-free surface. This is particularly important for applications where the coated wire will be exposed to harsh environments, such as outdoor use or industrial settings. The uniform coating not only protects the wire from corrosion and wear but also enhances its aesthetic appeal.

In summary, the high-precision PVC extrusion mold we have developed offers numerous benefits, including consistent product quality, extended mold life, and reduced maintenance costs. By applying this mold in a PVC wire coating production line, our clients can expect to produce high-quality, durable coated wires with greater efficiency and reliability. This advancement in mold technology is a testament to our commitment to delivering superior products that meet the needs of modern manufacturing.