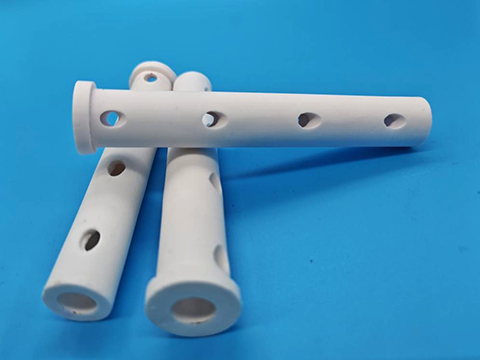

This article focuses on the ceramic nozzles for galvanizing lines, which are specially customized for the production equipment of galvanizing lines. These nozzles are not just standard components; they are tailored to meet the specific needs of each customer, ensuring optimal performance and compatibility with existing systems. Customized according to the specific dimensions provided by the customer, the manufacturing process is highly precise, with dimensional changes of only about ±1mm, ensuring high precision and reliability.

The production of these ceramic nozzles involves a meticulous process. First, a mold is custom-made based on the detailed drawings provided. This step is crucial to ensure that the final product matches the exact specifications required. Especially for this hole which is blank, a special process is needed to make a slanted hole to achieve a 45° angle between the pipe and the ceramic tube. This unique design allows for better alignment and functionality within the galvanizing line, enhancing the overall efficiency of the process.

These ceramic nozzles are specifically designed for durability and performance. They can withstand temperatures up to 100°C, making them suitable for a wide range of environments where thermal stability is of critical importance. In the galvanizing process, where high temperatures and corrosive substances are common, the ability to maintain structural integrity and functionality is essential. These nozzles offer consistent performance and long-lasting durability, reducing the need for frequent replacements and maintenance.

Whether used in manufacturing processes or as components of complex systems, these nozzles offer consistent performance and long-lasting durability. Their customizability and precision make them a valuable choice for industries that require high-quality and reliable materials. In the context of galvanizing lines, these ceramic nozzles play a vital role in ensuring the smooth operation of the process, protecting the equipment from wear and tear, and maintaining the quality of the galvanized products.

In summary, ceramic nozzles for galvanizing lines are more than just components; they are engineered solutions that enhance efficiency, reliability, and performance in industrial settings. Their ability to withstand harsh conditions and their precise customization make them indispensable in modern galvanizing operations.