Candid's professional teams and experience enable to provide quality and cost-effective modularized isolation gates. The isolation gates are designed for bulk, dry materials in a variety of applications. The Isolation gates allow your maintenance team to perform preventive repairs safely and easily without having to remove the gate from service.

Design & Engineering Capacity

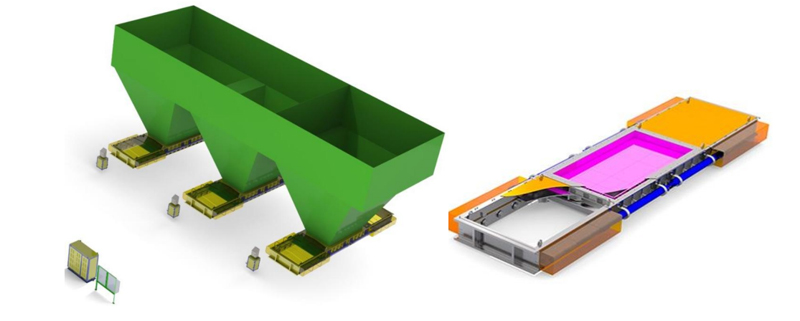

Dependent upon the size of the aperture to be isolated, Candid’s design features either a single-slide gate plate or dual-slide plates, closing from each end to the center.

The isolation gates are primarily fitted to safely isolate downstream equipment such as screens, feeders, and conveyors so they can be removed or worked on during maintenances.

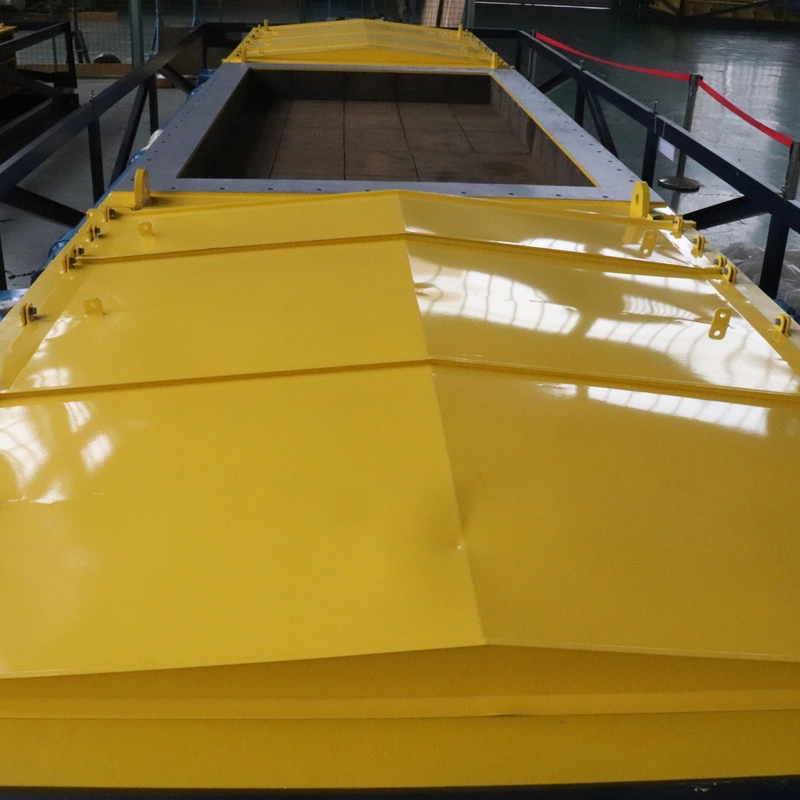

Developed for the needs of mining industry, Candid design and fabricate the heavy-duty bin isolation gates with opening apertures up to 10m long by 3m wide, and materials up to 400mm lump size with loading capacity up to 500 tons.

The isolation gate opening and closing operation can be designed to various driven methods, including manual, hydraulic, electric or pneumatic upon Client’s demands. Several successful installations have been undertaken across various industries such as crusher plant, material handling system, chemical engineering, etc.

![]() Modular Design, Shop Assembly and Testing

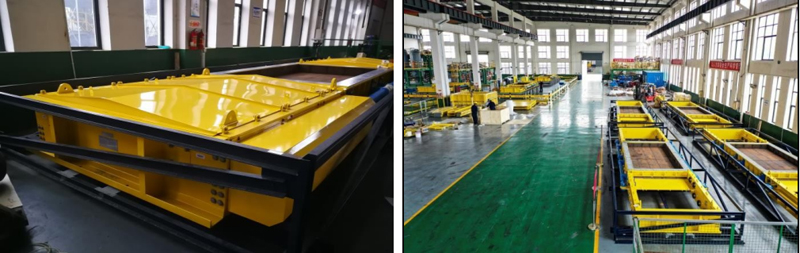

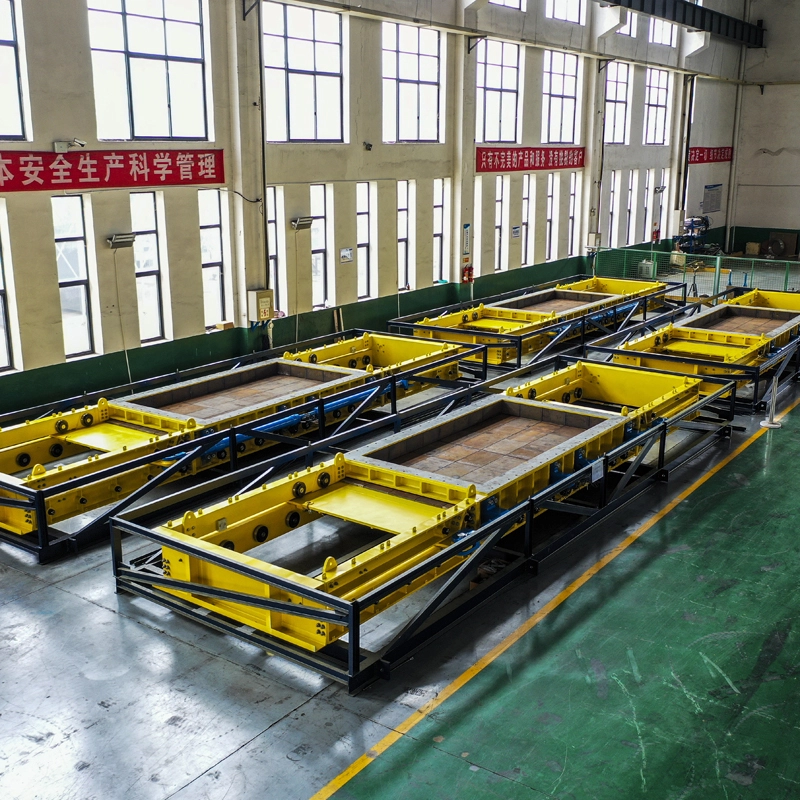

Modular Design, Shop Assembly and Testing

Candid’s heavy-duty isolation gate system is divided into several modular packages, including gate unit (c/w hydraulic cylinders), hydraulic power pack (c/w valve station), and the electrical and control unit.

All the packages are designed, fabricated, pre-assembled/assembled and tested in Candid's workshops. We optimize the fabrication processes, improve product quality, and reduce the total installed cost and site construction workload.

Our Approach

Candid uses advanced design and manufacturing technology to offer quality isolation systems at a reasonable cost to our clients worldwide.

Candid’s modularized isolation gate system provides reliable long-term performance in the smallest possible space. We use the best international brand name components and low-cost manufacturing centers world-wide.

The modular isolation gate systems have replaced the obsolete customized solutions. This concept enables end users to choose proven isolation gate systems with standardized assemblies that significantly reduces the design cost and construction schedule. Significant operations and maintenance savings are realized by using quick connections and fittings allowing component exchanges instead of inefficient field maintenance and downtime.

Gates & Accessories

Candid offers an excellent selection of manual, pneumatic, hydraulic, or electric operators to suit your specific demands. Our innovative design provides the platform for a variety of actuators.

Customizable options give our customers the ability to change the type of actuator, even after initial installation as your needs may change over time.

Components

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China