Steel Wire: Most commonly used material, providing strength and durability, essential for various nail types and sizes in production.

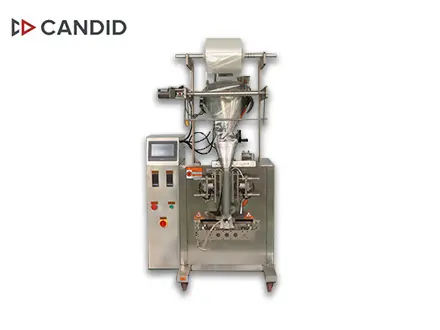

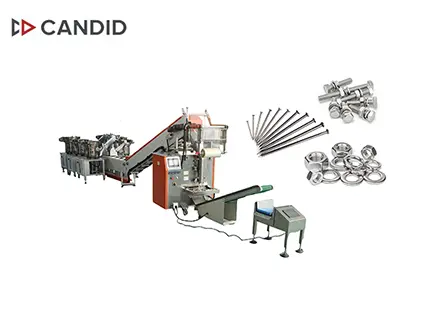

Nail making machines are essential equipment in the manufacturing of nails, widely used in construction and various industries. These machines automate the nail production process, increasing efficiency and reducing labor costs. Typically, they transform wire into nails through a series of operations, including cutting and forming. Then the nails need to be treated by nail polishing machine to ensure the good appearance. Modern nail making machines are designed for high-speed production and can handle various nail types and sizes. With advancements in technology, these machines now offer enhanced precision and reliability, ensuring consistent quality. As demand for fasteners continues to rise, nail making machines play a crucial role in meeting industry needs, so it develops different form like coil nail, roofing nail, double cap model etc. Whatever you need for nails, you can always go with CANDID

Steel Wire: Most commonly used material, providing strength and durability, essential for various nail types and sizes in production.

Aluminum Wire: Lightweight and corrosion-resistant, aluminum is ideal for specialized nails used in specific applications, such as roofing or decorative purposes or rivet

Stainless Steel: Offers superior resistance to rust and corrosion, making it suitable for nails used in outdoor or marine environments, especially for making concrete nail.

Copper Wire: Less common but used for certain types of nails, particularly in electrical applications or when aesthetics are important.

Coated Wire: Wire coated with materials like zinc or polymer enhances corrosion resistance and improves the finish of the final product while makes the surface brighter.

Specialty Alloys: Some machines can work with alloyed metals, providing unique properties like increased strength or flexibility for specific nail applications.

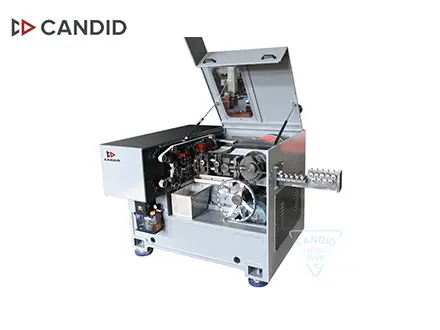

To improve the quality of nails produced, start by selecting high-quality raw materials, such as durable steel or stainless steel. Ensure precise calibration of the nail making machine to maintain consistent dimensions, for example, lower the speed if the current speed is fast enough, or check the cutter and moulds period. Regularly maintain and lubricate machinery to prevent wearing parts. Implement quality control checks throughout the production process to catch defects early. Optimize the manufacturing speed to avoid overheating or deformities. Additionally, consider investing in advanced technology to enhance accuracy and reliability. We will train operators on best practices, which can also improve overall production quality.

Regular maintenance of a nail making machine is essential for optimal performance and longevity. Key tasks include daily inspections for the wearing parts, ensuring all moving parts are properly lubricated to prevent friction. Monthly checks should focus on electrical connections and control systems to ensure safe operation. It's important to clean the machine regularly to remove debris and metal shavings, which can impede function. Additionally, replacing worn-out components, such as dies and cutters, should be scheduled to maintain production quality. A thorough annual maintenance review by a qualified technician can help identify potential issues before they escalate.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China